RH Journal Edition

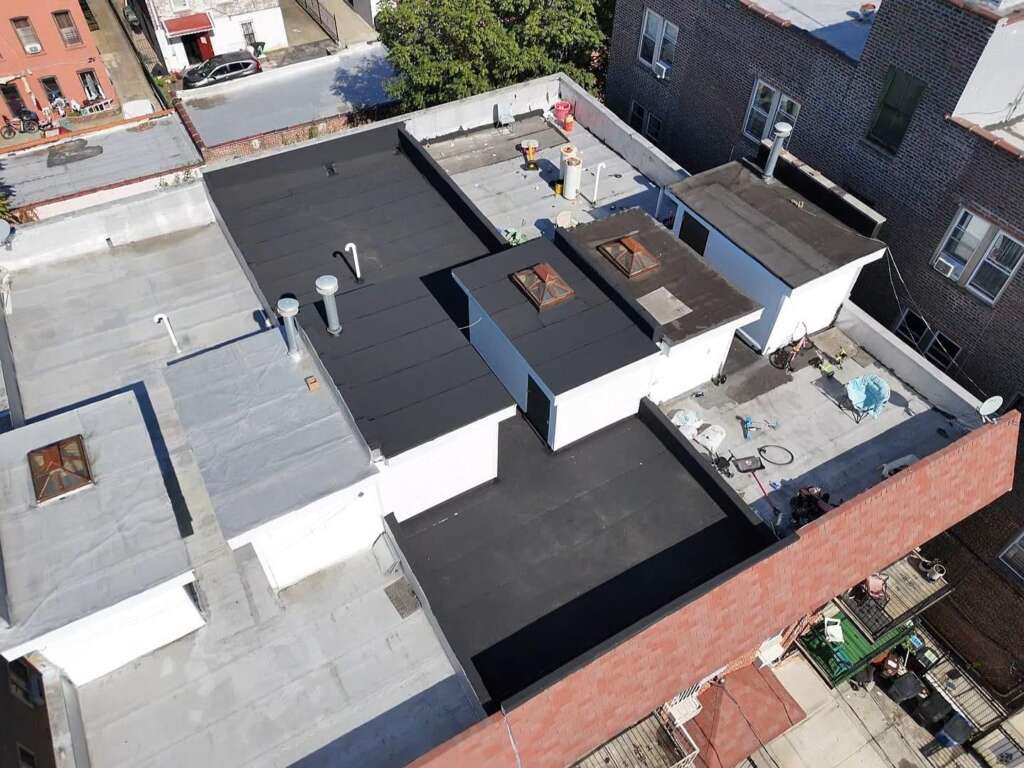

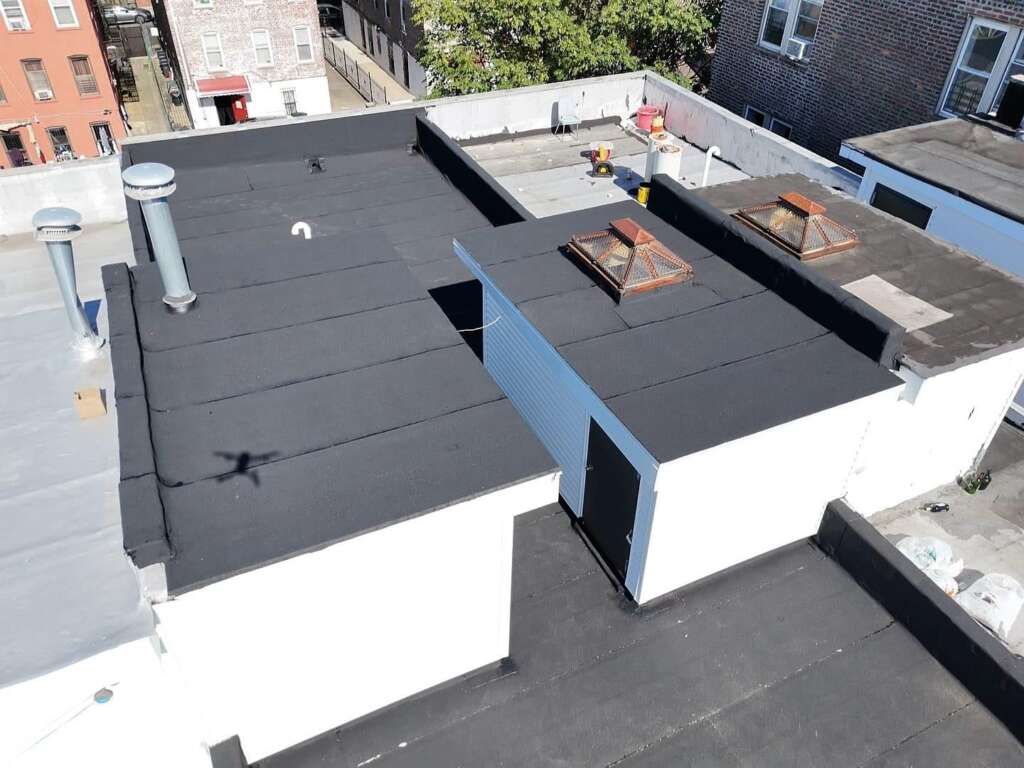

Residential Flat Roof System Replacement In Bronx, NY

Project Goal

The objective of this project was the complete removal and replacement of the existing compromised flat roof system to eliminate leaks, address water ponding, and upgrade the structure with a durable, energy-efficient, and code-compliant modern waterproof membrane system, providing decades of protection for the client’s investment in The Bronx.

RH Editorial TeamOctober 15, 2025 — NYC

Duration

3 min read

Detailed Scope of Work Completed

The work performed by RH Renovation LLC was executed in strict adherence to industry best practices and NYC Building Code requirements:

1. Preparation and Site Safety

- Permitting: Secured all necessary NYC Department of Buildings (DOB) permits and notifications.

- Protection: Erected proper site protection, including a sidewalk shed (if required) and ground coverings to protect adjacent property and ensure pedestrian/worker safety throughout the process.

- Debris Management: Conducted a safe and efficient full tear-off and legal disposal of all old roofing materials down to the substrate.

2. Substrate Preparation and Drainage Correction

- Deck Inspection: Performed a detailed inspection of the exposed roof deck (wood or concrete). Replaced or repaired all areas of damaged, deteriorated, or wet sheathing/decking to ensure a smooth, secure surface.

- Insulation & R-Value Upgrade: Installed new, high-density Polyisocyanurate Insulation Board to meet current energy code requirements and significantly improve the building’s thermal resistance (R-Value).

- Ponding Correction: Installed Tapered Insulation Systems to build a slight slope (cricket system) across the roof surface, effectively directing water towards drains/scuppers and eliminating chronic ponding issues.

3. Installation of New Membrane System

- Vapor Barrier: Installed an appropriate vapor barrier to prevent moisture migration into the new insulation layers.

- Membrane Application: Installed a premium, multi-layered flat roofing system (typically Self-Adhering Modified Bitumen or Heat-Welded TPO/PVC) according to the manufacturer’s exact specifications.

- Note: All seams were meticulously sealed (either heat-welded or chemically adhered) to create a monolithic, impenetrable waterproof envelope.

- Reflective Coating (If Applicable): Applied a highly reflective liquid coating (for Mod-Bit systems) or utilized a white membrane (for TPO/PVC) to dramatically reduce the roof surface temperature and lower interior cooling costs.

4. Flashing and Detailing

- Parapet Walls & Curbs: Installed the roofing membrane and flashing up all vertical surfaces (parapet walls, equipment curbs) to required height, securely sealing all termination points.

- Penetrations: Replaced or flashed all pipe vents, HVAC units, skylight curbs, and other roof penetrations with reinforced materials and specialized liquid flashing to guarantee a watertight seal at the most vulnerable areas.

- Drainage Points: Ensured all roof drains, scuppers, and overflow drains were properly cleaned, connected, and flashed into the new membrane.

5. Quality Assurance and Cleanup

- Final Inspection: A supervisor conducted a final, comprehensive inspection to confirm adherence to all project specifications and manufacturer installation standards.

- Cleanup: Conducted a final, thorough cleaning of the rooftop and surrounding site, removing all debris, fasteners, and excess materials.

Warranty and Trust

As a leading exterior contractor in The Bronx, RH Renovation LLC guarantees the longevity of this flat roof investment:

- Workmanship: Backed by a Workmanship Guarantee directly from RH Renovation LLC.

- Materials: Protected by the manufacturer’s Non-Prorated Material Warranty on the installed membrane system.